APIs can be outlined as being the biologically active factors within pharmaceutical formulations. They're the chemical compounds exclusively selected for his or her ability to exert a therapeutic impact on your body.

(biotech) refers to the use of cells or organisms which were produced or modified by recombinant DNA, hybridoma, or other know-how to make APIs. The APIs produced by biotechnological procedures Generally consist of substantial molecular excess weight substances, for instance proteins and polypeptides, for which precise direction is provided On this Part.

Commercially offered computer software that's been experienced will not call for the exact same amount of screening. If an existing process wasn't validated at time of installation, a retrospective validation could be conducted if ideal documentation is accessible.

Packaged and labeled intermediates or APIs ought to be examined to ensure that containers and deals inside the batch have the proper label. This examination really should be part of the packaging operation. Success of such examinations must be recorded inside the batch creation or Management documents.

Retest Day: The day when a material should be re-examined to make certain that it is still suited to use.

Any deviation from founded procedures ought to be documented and described. Important deviations really should be investigated, as well as investigation and its conclusions need to be documented.

All output, Command, and distribution information must be retained for at least one calendar year following the expiry date on the batch. For APIs with retest dates, records ought to be retained for at least three several years once the batch is totally distributed.

Materials to get reprocessed or reworked ought to be appropriately managed to prevent unauthorized use.

Strategies should be recognized to reconcile the quantities of labels issued, made use of, and returned and To guage discrepancies uncovered among the volume of containers labeled and the number of labels issued.

From this issue on, correct GMP as outlined In this particular steering needs to be applied to these intermediate and/or API manufacturing steps. This would come with the validation of essential approach methods determined to affect the quality of the API.

Reliable certificates of research must be issued for each batch of intermediate or API on ask for.

The expiry or retest date with the blended batch need to be according to the manufacturing day on the oldest tailings or batch inside the Mix.

Samples needs to be consultant with more info the batch of material from which they are taken. Sampling techniques really should specify the amount of containers to become sampled, which part of the container to sample, and the amount of material to get taken from each container.

obligations of your impartial excellent device(s) really should not be delegated. These duties needs to be explained in producing and will contain, although not always be restricted to:

Sydney Simpson Then & Now!

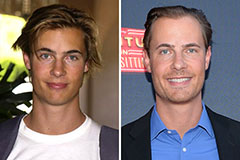

Sydney Simpson Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Mason Reese Then & Now!

Mason Reese Then & Now! Lisa Whelchel Then & Now!

Lisa Whelchel Then & Now! McKayla Maroney Then & Now!

McKayla Maroney Then & Now!